Compared with other similar products, ZW self-priming sewage pump has the characteristics of simple structure, good self-priming performance, strong sewage discharge capacity, high efficiency and energy saving, convenient use and maintenance, etc. It is a domestic pioneer in the series of sewage pump products. The technical performance indicators are leading domestically, reaching the international advanced level, with broad application market and development prospects.

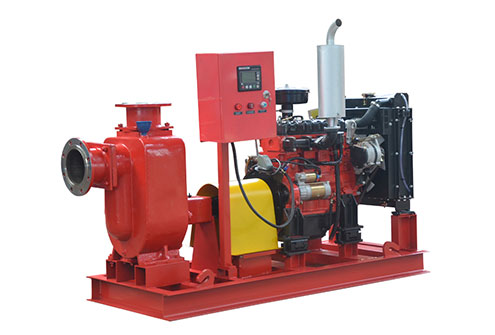

ZW self-priming diesel fire pump integrates self-priming and non-blocking sewage discharge. It adopts axial recirculation and external mixing, and through the unique design of pump body and impeller flow channel, it can be installed like the general self-priming pump without the bottom valve. It can be used for municipal sewage treatment projects, river pond culture, light industry, papermaking, textile, food, chemical industry, electrical industry, fiber, slurry and mixed suspension, etc. It can pump water and absorb liquids containing large particle solids and long fiber impurities. It is the most ideal impurity pump for chemical media.

ZW self-priming fire pump scope of use:

1. In regard to the medium PH value , the cast iron pump is 6-9, and the stainless steel pump is 1~14.

2. Ambient temperature is less than or equal to 45 ° C, medium temperature is less than or equal to 60 ° C.

3. The maximum diameter of the particles is 60% of the pump diameter, and the fiber length is 5 times of the diameter.

4. The total weight of impurities in the medium does not exceed 15% of the total weight of the medium, and the proportion of the medium does not exceed 1240 kg/m³.

The seals wear replacement:

1. Check if all parts are damaged during transportation.

2. Check whether the base is horizontal before installation.

3. The pump itself is not allowed to be as a pipeline support.

4. The pump and pipes should be well sealed.

5. Check if the fasteners on the pump base, coupling, bearing and other connecting parts are loose. If loose, should be fastened.

6. Is there any jam or abnormal sound when the coupling is turned by hand?

7. Open the watering valve above the pump and add not less than two-thirds of the volume of the pump, then close the valve. No need to re-inject water after starting up.

8. Connect the power supply and try to turn it. Seen from the motor end, it should be turned clockwise.

9. Check whether the running is normal. If there is an abnormal phenomenon, found the causes and excluded.